For nearly 25 years, visitors to Seymour Marine Discovery Center, operated by the University of California, Santa Cruz, have been greeted by Ms. Blue, the largest outdoor blue whale skeleton on display in the US. So when the bones began deteriorating, Seymour Center began looking for ways to preserve Ms. Blue and do so using sustainable methods. Hollywood VFX studio Halon Entertainment proposed a solution involving laser scanning, 3D printing, 3D modeling and animation, an AR component, and more. As a result, the physical Ms. Blue is being repaired and will soon be ready to greet visitors once again. Also, a new exhibit will feature animations, and an AR app provide information about blue whales and even Ms. Blue herself that enable visitors to bone up on this amazing animal.

In the 2006 fantasy film Night at the Museum, Hollywood brings the giant Rexy, a Tyrannosaurus rex skeleton, and other museum exhibits and artifacts to life. In what is an example of life imitating art, Seymour Marine Discovery Center’s skeletal display, this one of a giant blue whale, likewise has been brought back to life using some of the same Hollywood magic, this time more for educational, rather than pure entertainment, purposes.

For two and a half decades, the skeletal structure, named Ms. Blue, has graced the outside of the marine research facility and museum, operated by the University of California, Santa Cruz.

Many consider Ms. Blue a cultural landmark. The 50-year-old blue whale washed up on shore at Pescadero Beach, near Seymour Marine Discovery Center, in 1979. Students and faculty from UC Santa Cruz transported the colossal creature piece by piece to the center, where the specimen underwent marine research and study. The remaining bones were then preserved and mounted for display in front of Seymour Center.

However, exposure to the outdoor elements has led to deterioration of the whale bones on its mounted steel structure, and as a result, the center began looking at options for preserving its beloved greeter for future generations.

According to Jonathan Hicken, executive director of the center, a number of preservationists and fossil specialists they consulted with suggested using a plastic-like covering to protect the bones, which “sent the wrong message regarding conservation,” Hicken said, that was contrary to Seymour Center’s ideology.

Halon Entertainment, a well-known visual effects studio, came up with an alternative that reflected the values of Seymour Center. By using digital scanning and 3D printing, physical replacements and repairs of damaged and worn bones could be made and used in the physical display, enabling Ms. Blue to continue greeting visitors into the future. What’s more, the data from the scans could be used to make a digital replica of the whale, which could be animated and made into an additional exhibit.

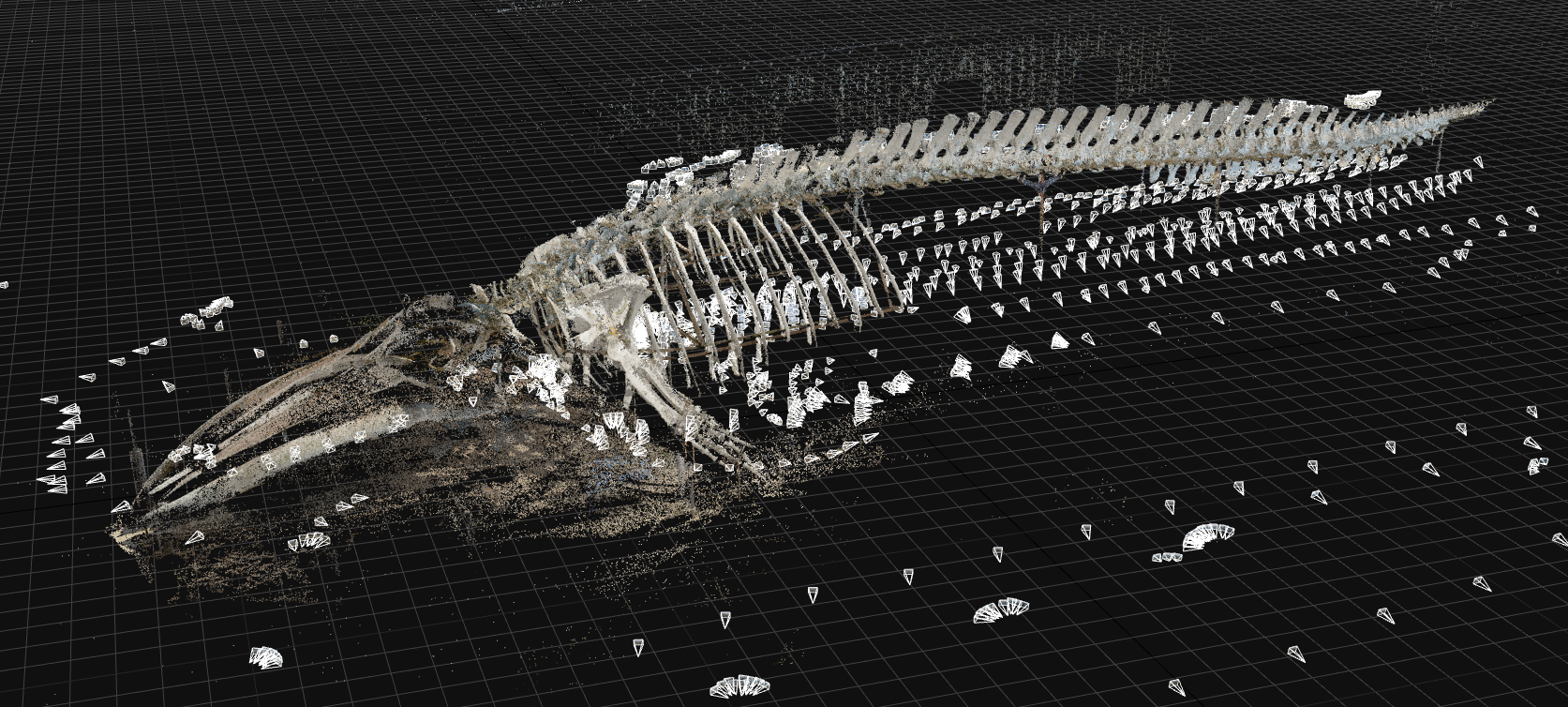

Using a portable Leica RTC360 3D laser scanner—capable of capturing data at up to 2 million points per second—the Halon team began scanning the 87-foot skeleton. The process took less than a day, with the group capturing a total of 53 lidar scans.

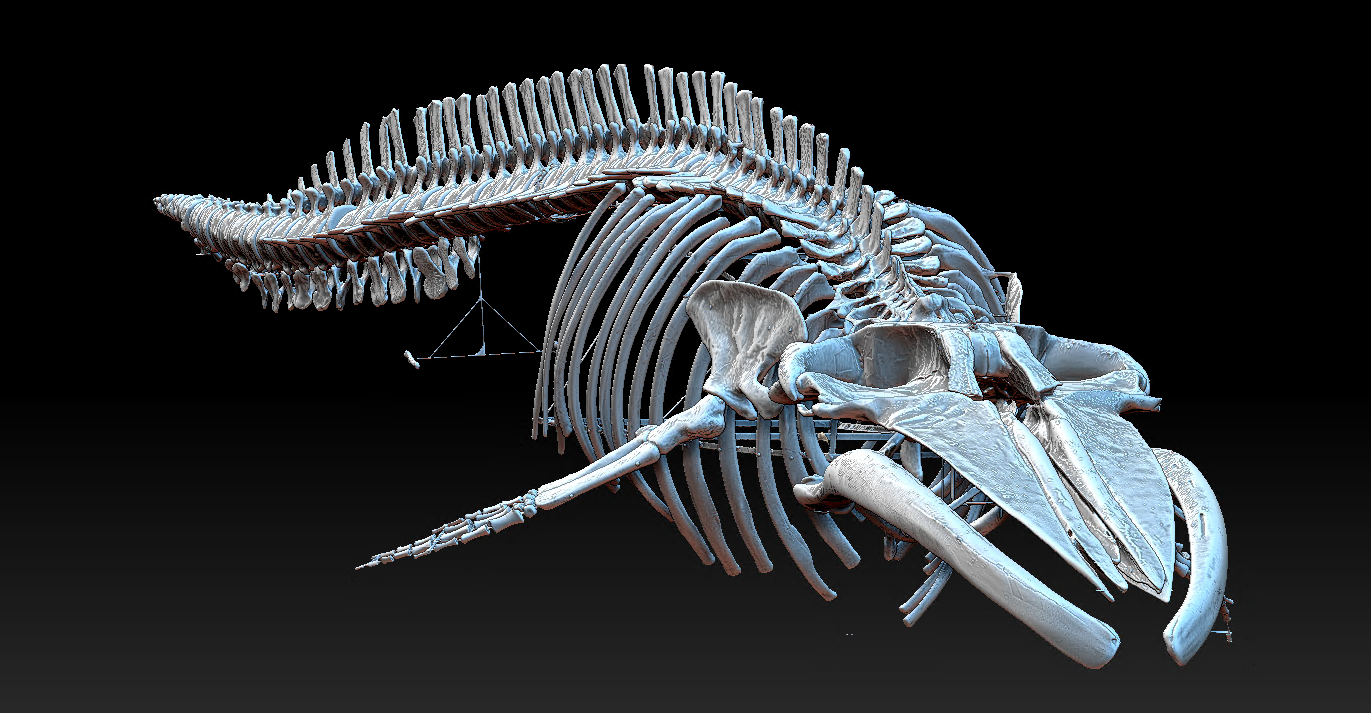

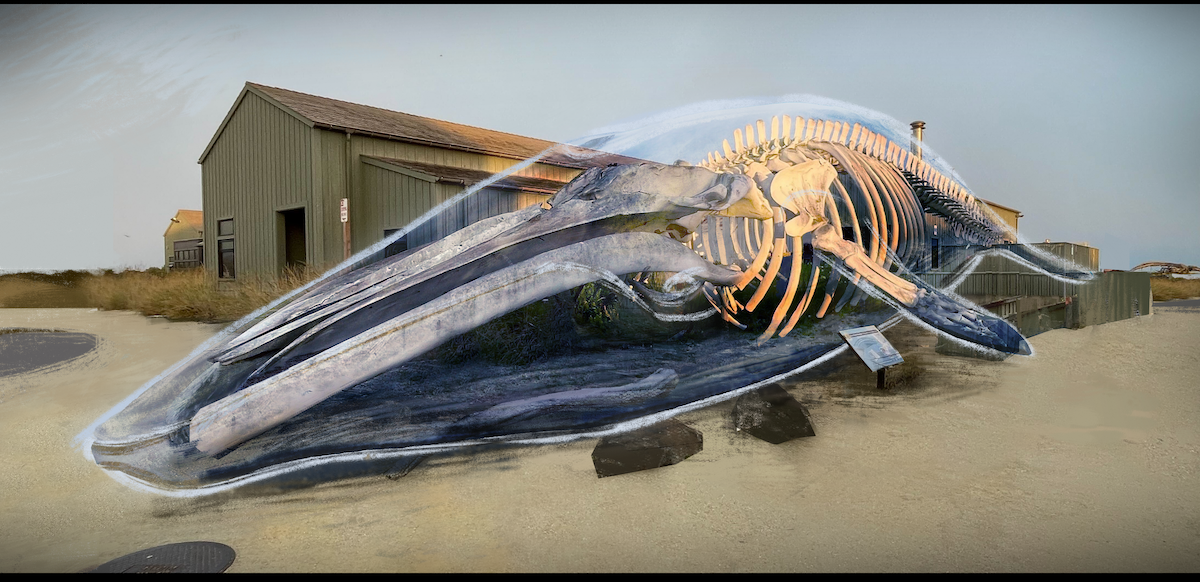

Halon then used the lidar data to create a photorealistic 3D model of Ms. Blue, using Maxon’s ZBrush and Adobe’s Substance Painter to add digital skin and muscle. Using Autodesk’s Maya, the VFX artists reconfigured and repositioned the creature before uploading the file into the Unity game engine, where the Halon team created a series of animations based on the movement of whales like Ms. Blue in their natural environments. The VFX artists also built an app that enables students and visitor to interact with four animated lessons focused on the life of blue whales. They also generated an AR component that shows Ms. Blue as she once was.

The four animated lessons will be available to visitors in the near future.

Meanwhile, Seymour Center is planning the return of the repaired physical Ms. Blue to its previous location outside the center in a few months. 3D-printed replicas are being made for the larger bones that are too heavily damaged to preserve. These are being made by Swellcycle, known for creating sustainable surfboards. Using dozens of lidar scans from the Leica RTC360, the 3D printing team is replicating the bones down to the grooves in the originals, using printing materials made from recycled hospital trays.

For the original bones that are still viable but damaged, engineering professors and students at UC Santa Cruz developed a unique powdered putty, created from shrimp shells—coincidentally, one of the primary sources of food for blue whales. A few additional bones have been archived for future research, including a proposed project aimed at tracing Ms. Blue’s origins and potentially identifying her descendants, according to the center.

LIKE WHAT YOU’RE READING? INTRODUCE US TO YOUR FRIENDS AND COLLEAGUES.